Phone: 0033 983 795 995

Mentions legales

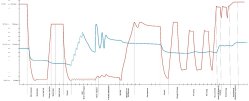

Our sterilization cycle is based on a vacuum cycle using preferably pure ETO and Nitrogen in order to have a non flammable mixture during cycles.

The process is controlled through four parameters:

- Gas concentration

- Temperature

- Relative humidity

- Exposure time.

Performing a high level of qualification and associated with a good preventive maintenance program, these equipment are efficient, repeatable and reliable.

EtO sterilizers can be associated to other equipment such as:

- Preconditioning cell : To warm and reach good humidity set point inside the product before sterilization cycle to save production time

- Desorption cell : To remove EtO residual from the sterilized products

- Conveyors system : To increase efficiency and process optimization

- Tracking system : To perform in production quality system

In order to achieve the sterilization cycles and process parameters MDS builds standard or custom made cycles, including various sequences . Each sequence can be time or parameter driven and in any case the transition can only be allowed if the previous one has been achieved successfully.

Our programs and supervision interfaces are fully documented and answer the 21CFR Part 11 and GAMP requirements.